For food and beverage manufacturers, internal audits are more than a compliance requirement. These are the backbone of a strong food safety culture. Whether you’re packaging, processing or distributing food, the ability to assess your own systems is one of the most effective ways to build customer confidence.

More Than a Checkbox

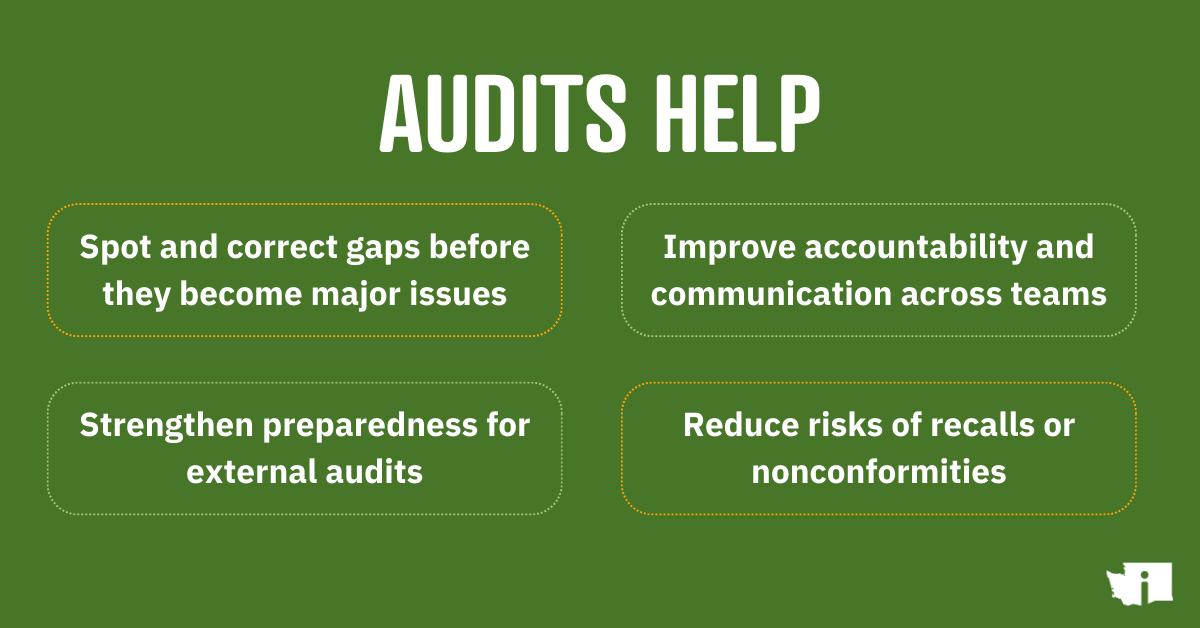

Internal audits are often seen as a checkbox requirement for certification schemes like SQF, BRC, or FSSC 22000, as well as many third-party programs. But they’re much more than that. A strong internal audit program is one of the most effective ways to catch issues before they escalate, build trust with customers, and create a culture of accountability across your facility.

Think of them as a safety net. By evaluating your systems from the inside, you not only stay ready for third-party audits but also strengthen the everyday practices that keep your products safe and your operations resilient.

Building Skills That Last

Running an effective internal audit requires more than a checklist. Auditors need to know how to prepare, ask the right questions, gather objective evidence, and report results in a way that drives action. They also need the confidence to engage colleagues, highlight risks, and foster improvement, not blame.

That’s why Impact Washington is offering a two-day online Internal Auditing for Food Safety Workshop. It’s designed for food safety and quality managers, plant leaders, HACCP team members, those who are new to internal auditing or anyone who needs a refresher course in auditing.

Download the Internal Auditing for Food Safety workshop information sheet here to learn more.

Participants will walk away knowing how to:

- Plan and conduct an audit from start to finish

- Use effective techniques for interviews, observations, and note-taking

- Spot and report nonconformities clearly

- Ensure follow-up actions drive lasting improvements

Why Now Matters

As standards and customer expectations rise, manufacturers that invest in strong auditing practices are better positioned to stay competitive and resilient.

Help your team meet certification requirements and strengthen your overall food safety program.