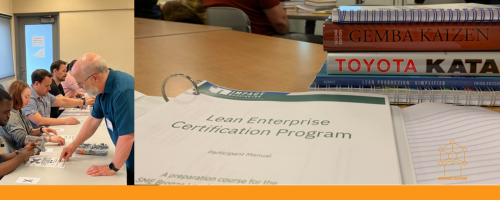

Impact Washington’s Lean Enterprise Certificate Program (LECP) is an exceptional starting point for any manufacturer seeking to embark on a transformative continuous improvement journey. Developed by the esteemed Society of Manufacturing Engineers (SME), this program equips participants with essential Lean training and experience, empowering them to become true "Lean Champions" within their company.

Throughout the LECP Program, participating employees gain fluency in the universal language of lean principles. They learn to draw a current state map, analyze existing processes, identify non-value-added activities, and envision a future state map that eradicates unnecessary actions and waste.

The outcomes of this comprehensive training are nothing short of remarkable:

- A Foundation of Continuous Improvement: Manufacturers establish a strong foundation for their ongoing efforts towards continuous improvement. The LECP Program instills a culture of growth and innovation, driving organizations towards excellence.

- Comprehensive KPI Visibility through Visual Factory Tools: Manufacturers attain enhanced Key Performance Indicator (KPI) visibility by implementing visual factory tools. This exercise empowers teams to make data-driven decisions and respond proactively to challenges.

- Superior Customer On-Time Delivery Performance: With insights gained from the LECP Program, manufacturers experience a significant improvement in customer on-time delivery performance. Achieving delivery rates of 90% and beyond becomes a reality.

- Streamlined Workflow through One-Piece Flow: Manufacturers transition from traditional batch processes to the efficient one-piece flow method, successfully meeting the escalating demands of their customers.

- Enhanced Concurrent Engineering for Future Product Launches: By incorporating increased concurrent engineering practices, manufacturers are better equipped to navigate the development of future product launches seamlessly.

- Waste Reduction through Dedicated Boards: Waste reduction boards become a powerful tool for manufacturers to pinpoint and tackle waste across all eight waste categories. These tools foster a lean, efficient, and sustainable production environment.

- Shared Language of Continuous Improvement: Perhaps most importantly, employees across all levels of the organization unite under a common language of continuous improvement. This shared understanding facilitates seamless collaboration and promotes a unified drive for progress.

The LECP Program empowers manufacturers to unleash their true potential, fostering a culture of excellence and adaptability. By embracing Lean principles and practices, manufacturers can optimize operations, maximize customer satisfaction, and secure a prosperous future in an ever-evolving industrial landscape.

Contact us here to learn how we can bring an LECP Program to your facility and let your manufacturing enterprise soar to new heights of efficiency, innovation, and success.